High-speed machining is a method of metal processing utilizing CNC machine tools, characterized by higher cutting speeds and feed rates. Consequently, the requirements for cutting tool materials are very stringent. Proper selection of cutting tool materials is crucial for ensuring the quality of high-speed machining.

Cutting tools are the most important implements in machining and significantly influence the development of processing technologies. The performance indicators of tool materials directly affect their machining performance, processing capability, and machining quality.

Currently, numerous types of tool materials are used in high-speed machining, including cemented carbides, ceramics, cubic boron nitride (CBN), and diamond. It is necessary to determine the requirements for tool materials based on the workpiece material, processing conditions, and performance demands.

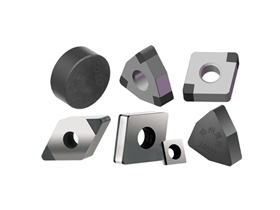

1、Cemented Carbide Tools. Cemented carbide tools are classified based on tungsten carbide, and can be categorized into tungsten-cobalt (WC-Co) types, tungsten-titanium-cobalt (WC-TiC-Co) types, and those with rare carbides added. To meet the demands of high-speed machining, their mechanical properties can be enhanced by applying coatings to the tool surface. Based on whether they are coated or not, cemented carbide tools can be further divided into coated cemented carbide tools and uncoated cemented carbide tools.

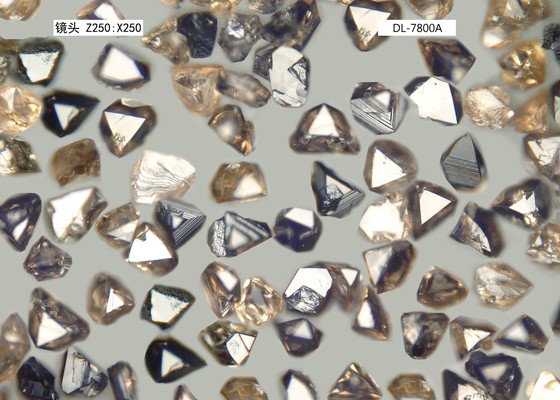

2、Diamond Tools. Diamond tools can be divided into two types. The first is single-crystal diamond (SCD) tools, which can be used for ultra-precision machining of materials such as red copper, copper alloys, and various precious metals. They inherently possess a grain boundary-free structure, allowing the cutting edge to theoretically achieve atomic-level smoothness and sharpness, resulting in high cutting precision.

The second type is polycrystalline diamond (PCD) tools, which can be subdivided into polycrystalline diamond (PCD) tools and chemical vapor deposition (CVD) diamond tools. The former are generally used for machining non-ferrous metals, ceramics, cemented carbides, and composite materials. The latter have material properties close to those of natural single-crystal diamond and are often used as substitutes, capable of reducing costs to a certain extent.

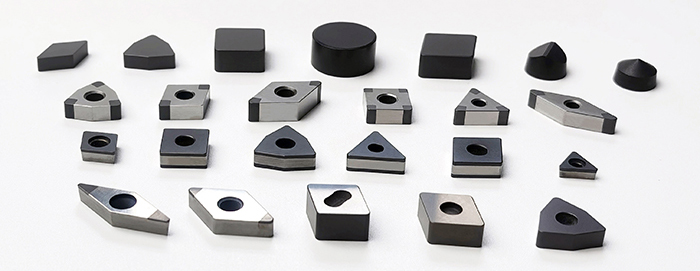

3、Cubic Boron Nitride (CBN) Tools. Cubic boron nitride material possesses hardness second only to diamond, while its thermal stability and chemical stability are even higher than diamond's. It can machine materials like hardened steel and high-temperature alloys while maintaining normal cutting speeds. CBN tools offer many advantages, such as high machining efficiency and good surface roughness of the product. Coolant is not required during machining, giving them good environmental friendliness.

4、Ceramic Tools. Ceramic tools can be divided into alumina-based ceramic tools and silicon nitride-based ceramic tools. Compared with cemented carbide tools, ceramic tools are significantly superior in hardness, wear resistance, heat resistance, bending strength, elastic modulus, etc. Furthermore, the material itself has low affinity with metals; even in a molten state, it does not react with metal. Issues like wear, oxidation, and adhesion rarely occur during high-speed machining.