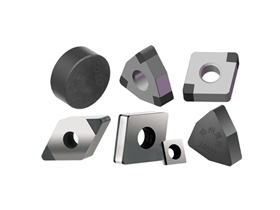

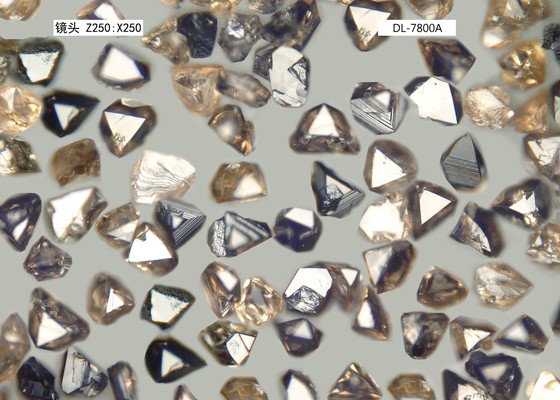

Sintering synthetic diamond under high temperature and high pressure produces polycrystalline diamond (PCD). PCD possesses excellent mechanical properties, such as extreme hardness and wear resistance, high thermal conductivity, and a low coefficient of friction. Based on these properties, PCD cutting tools have found wide applications in industry.

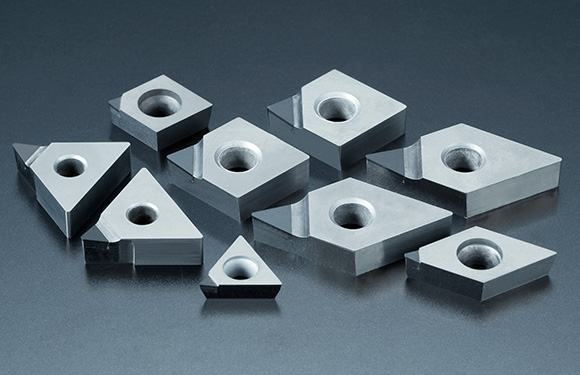

I. Performance of PCD Cutting Tools.

1. High Hardness and High Wear Resistance. PCD is currently the hardest man-made material in the world, with a hardness reaching approximately 1000 HV. Additionally, due to its isotropic nature, PCD exhibits exceptional wear resistance.

2. Low Coefficient of Friction. The coefficient of friction of PCD is lower than that of other materials, about half that of cemented carbide. Utilizing the low coefficient of friction of PCD ensures high surface quality of the workpiece during machining.

3. High Thermal Conductivity. PCD cutting tools possess excellent thermal conductivity, allowing for rapid dissipation of cutting heat during machining. This ensures that the required cutting temperature is maintained.

4. High Machining Precision. Due to its low thermal expansion coefficient and high elastic modulus, PCD tools exhibit minimal deformation during cutting, maintain sharpness over long periods, and deliver high cutting precision.

II. Applications of PCD Cutting Tools.

1. Application in the Automotive and Aerospace Fields. Modern technological fields such as the defense industry, microelectronics industry, automotive engineering, and aerospace require precision and ultra-precision machining. Due to their high durability, high dimensional accuracy in machining, and ability to achieve excellent workpiece surface roughness, PCD tools are commonly used in the automotive and aerospace sectors. For example, in the aircraft industry, to reduce weight, lightweight materials are increasingly used, with aluminum alloys seeing growing application. Compared to traditional cutting tools, especially cemented carbide tools, using PCD tools not only increases tool life but also significantly improves cutting speeds.

2. Application in the Wood Processing Field. PCD tools are also widely used in wood processing. For instance, the structure of laminated flooring is relatively special. General cemented carbide tools, due to their lower hardness and poorer wear resistance, yield unsatisfactory processing results. Utilizing the extremely high hardness and wear resistance of PCD tools perfectly solves this problem.

3. Application in the Electronics Industry. With the continuous development of the electronics industry, the requirements for the production level of printed circuit boards (PCBs) are increasingly high. When using conventional tools to machine PCBs, phenomena like burring on cut edges and slots frequently occur. Using PCD tools, machining linear speeds can reach 1500-2000 m/min, and burring does not occur when cutting edges or slots.

4. Application in the Petroleum Geological Drilling Industry. PCD drill bits are sharp-cutting, robust, wear-resistant, and capable of self-sharpening. When used for drilling, they achieve drilling speeds and footage rates unattainable by traditional materials. Compared to roller cone bits, PCD drill bits offer higher safety and greater working efficiency.