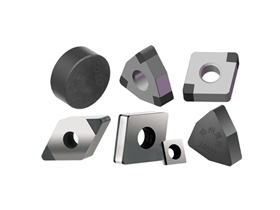

Polycrystalline diamond compact (PDC) is a superhard material composed of diamond powder and a cemented carbide substrate compounded under high-temperature and ultra-high-pressure conditions. It is widely used in industries such as petroleum and geological exploration, and mechanical machining tools. The cemented carbide substrate material, with its excellent toughness, hardness, and weldability, provides a solid foundation for the PDC.

As the key cutting element of drill bits, the performance of the PDC compact directly impacts the working efficiency and service life of the bit. The polycrystalline diamond layer is the main working part of the PDC, and its thermal stability in high-temperature environments significantly influences wear resistance and cutting efficiency. Therefore, enhancing the thermal stability of the PDC compact is key to optimizing its overall performance.

1. Selection and Control of Binder

Cobalt is commonly used as the binder in the polycrystalline diamond layer because it improves the wettability of diamond and facilitates the formation of D-D bonds through dissolution and recrystallization. However, under high-temperature conditions, the interaction between cobalt and diamond can lead to graphitization and volumetric expansion, subsequently causing delamination issues in the compact.

This is due to the significant differences in the thermal expansion coefficients between cobalt, diamond, and the substrate material, resulting in internal stresses at elevated temperatures. Therefore, selecting an appropriate binder and controlling its content are crucial. The interaction between the binder and diamond at high temperatures must be carefully considered to avoid catalyzing diamond graphitization, which affects the thermal stability of the PDC.

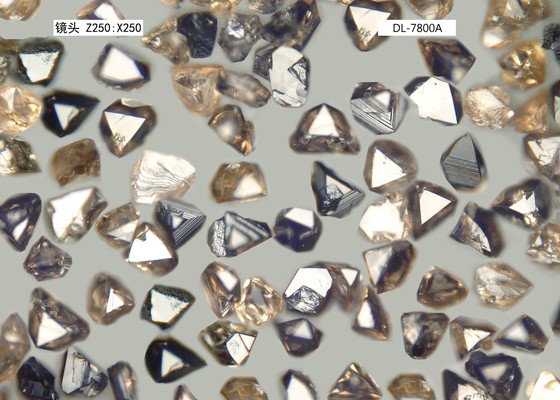

2. Optimization and Treatment of Diamond Raw Materials

The particle size, content, and treatment methods of the diamond raw materials directly affect the wear resistance, impact toughness, and thermal stability of the PDC. Selecting suitable diamond content and particle size according to specific processing requirements is essential. Furthermore, treating diamond raw materials through methods such as surface coating or physical property enhancement can significantly improve their thermal stability and resistance to graphitization. These treatment measures help enhance the performance of PDC compacts under extreme conditions.

3. Rational Application of Dopants

PDC diamond compacts mostly use WC-Co cemented carbide as the substrate. During the sintering process, cobalt from the substrate gradually infiltrates the diamond layer. Adding dopants can promote the uniform diffusion of catalytic metals, optimizing the performance of the compact.

Distributed on the diamond surface, dopants can both disperse stress, preventing particle detachment, and combine with diamond to form new phases, increasing the strength and density of the compact. Additionally, dopants can react with the binder to form metal carbides, filling material gaps and further enhancing the structural stability of the compact.

4. Innovative Improvements in Structural Design

Structural optimization of PDC compacts can significantly enhance their performance. Main methods include interface designs such as non-planar joining technology, multi-layer composite structures, and profiled surface structures. Different interface structure design forms can be adopted according to specific application requirements to reduce interfacial stress, minimize residual stress and spalling phenomena, and enhance the impact toughness of the compact.