"When other brands are still competing on hardness and price, Berlt has redefined the standard of 'ease of use' with an annual production capacity of 6 million inserts." — Zhengzhou Berlt

In the field of hard turning, what truly troubles users is never just "the material is too hard."

More often, it's the instability during the machining process: unpredictable insert life, high risk of chipping, frequent dimensional fluctuations, ultimately leading to downtime, rework, or even part scrap.

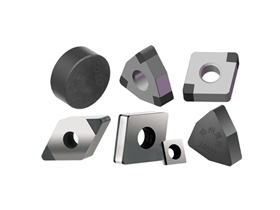

It is precisely for this reason that more and more users who prioritize stable delivery and long-term cost control are beginning to re-evaluate the selection criteria for PCBN inserts. And Berlt PCBN hard turning inserts have become a commonly used solution for hard turning users.

I. Hard Turning Imposes "Comprehensive Capability" Requirements on Inserts

Hard turning typically deals with hardened steels or high-hardness alloy materials above HRC55. The machining process involves high cutting temperatures, concentrated cutting forces, and frequent impact on the cutting edge.

This is not a problem that can be solved simply by the insert's "high hardness." Instead, it places higher demands on the insert material's stability, heat resistance, and cutting edge structure.

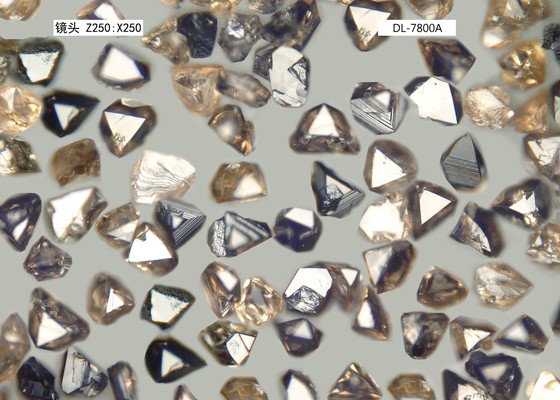

From the initial R&D and design phase, Berlt PCBN hard turning inserts have focused on hard turning conditions as the core application scenario. Through systematic optimization of CBN grain structure and binder, the inserts maintain stable cutting performance even under high-temperature, high-load conditions, avoiding the common problem of being "effective initially but losing control later."

II. Stability is the Most Real and Pressing Need for Hard Turning Users

Summarizing the actual usage scenarios of many customers, what hard turning fears most is not the end of a single insert's life, but unpredictable failure. A sudden chipping event may lead to out-of-tolerance dimensions, scrapped surface quality, and even forced production stoppages along with the workpiece.

In practical applications, the advantage demonstrated by Berlt PCBN hard turning inserts is precisely this "stable and controllable" machining experience:

·Insert life shows normal wear patterns, making the process more predictable.

·High cutting edge strength reduces the likelihood of sudden chipping.

·Stable and continuous machining over extended periods ensures consistent dimensional accuracy and surface quality.

This stability allows users to reduce disruptions from frequent insert changes and repeated machine adjustments in actual production, thereby focusing more energy on capacity and delivery itself.

III. The Shift from "Insert Cost" to "Cost Per Piece"

Many users can be easily influenced by unit price when selecting PCBN inserts. However, in hard turning, what truly determines cost is never the insert price, but the comprehensive machining cost allocated to each workpiece.

Berlt PCBN inserts help users achieve the following through higher efficiency and more stable machining conditions:

·Reduced frequency of insert changes, improving equipment utilization.

·Reduced manual intervention, leading to more stable production cycle times.

·Lower rework rates, significantly improving part yield.

When the machining process is sufficiently stable, the unit price of the insert is no longer the core issue, and the overall cost naturally decreases.

IV. Berlt's Advantages Stem from Deep Understanding of Materials and Applications

As China's first PCBN insert manufacturer, Berlt is not merely an insert producer but exercises systematic control from the material source to the finished insert. This gives Berlt PCBN inserts several distinct advantages in hard turning applications:

·High consistency in insert performance, suitable for stable batch production.

·Clear application boundaries and recommended solutions for different working conditions.

·Testable cutting geometries, with continuous assurance for volume production applications.

This means for users, it's not about "trying inserts by luck," but about establishing long-term, stable machining solutions. If you are currently facing issues with stability, efficiency, or overall cost in hard turning, Berlt PCBN hard turning inserts may become a more reliable long-term choice for your hard turning operations.