In the wind power industry, "stable operation for twenty years" is not a slogan but a rigid requirement for every set of bearings. As a key processing step for core components like wind turbine main shafts, yaw bearings, and pitch bearings, the quality of bearing turning directly determines the service life and maintenance costs of the entire unit.

It is precisely for this reason that more and more wind power bearing manufacturers are shifting from "being able to process" to "processing more stably, economically, and controllably." Under this trend, Berlt CBN inserts are becoming the preferred cutting tool solution for high-end wind power bearing turning operations.

I. What Are the Real Challenges in Wind Power Bearing Processing?

From the actual processing floor, wind power bearing processing faces not a single technical issue, but multiple overlapping pressures:

· High Material Hardness, Complex Structure: Bearing steels are mostly in a hardened state, typically with a hardness between HRC 58–65, placing extremely high demands on tool wear resistance and stability.

· High Single-Piece Value, High Cost of Error: Once edge chipping, chatter, or dimensional loss of control occurs, the loss is not just a single insert, but potentially an entire high-value workpiece.

· Stringent Requirements for Batch Consistency: Wind power bearings emphasize "long-term stable operation," making them highly sensitive to dimensional consistency and surface integrity.

· Persistent Cost Reduction Pressure: It's not just about the unit price of the insert; comprehensive machining costs, tool change frequency, and equipment utilization rates must be considered.

What truly matters on the processing floor is never "how impressive the insert parameters are," but whether the process is stable enough, costs are controllable in the long term, and risks are predictable.

II. Core Advantages of CBN Inserts for Machining Wind Power Bearings

CBN inserts are particularly suitable for turning hardened steels, offering far greater stability than traditional tools. CBN (Cubic Boron Nitride) material is naturally suited for hard turning due to its hardness, wear resistance, and thermal stability. Compared to traditional carbide or ceramic tools, CBN inserts maintain a more stable cutting condition under both continuous and interrupted cutting conditions, significantly reducing the risk of chipping and abnormal wear.

"Hard Turning Instead of Grinding," Shortening the Process Chain and Truly Reducing Costs. In wind power bearing processing, CBN inserts can directly complete high-precision hard turning, potentially replacing traditional grinding in some processes. This reduces process switching, shortens production cycles, and lowers equipment and labor costs. More importantly, hard turning offers greater flexibility, especially suitable for producing medium to large-sized wind power bearings of various models.

Stable Surface Quality, Directly Contributing to Bearing Life. Under proper parameters, CBN inserts can achieve stable surface roughness and sound surface structure, minimizing risks like burns, cracks, or white layer formation.

Strong Tool Stability, Good Consistency, Suitable for Mass Production. High-quality CBN inserts are not only "durable" but, more importantly, exhibit "batch-to-batch stability." In an industry like wind power bearings that emphasizes consistency, stable tool life and wear patterns mean more precise tool change schedules, more controllable machining quality, and lower management and trial-and-error costs.

III. Typical Application of Berlt CBN Inserts in Machining Wind Power Bearings

Workpiece Name: Wind Power Slewing Bearing

Workpiece Material: 42CrMo, HRC 58-62

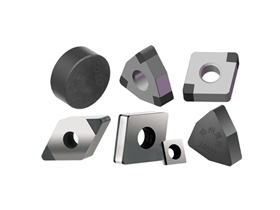

Insert Model: Berlt BTS6500, RCGX0907

Cutting Parameters: Vc = 150 m/min, F = 0.25 mm/r, ap = 0.5 mm

Result: The Berlt CBN insert processed 2 workpieces with normal wear; another brand's insert failed due to chipping after processing only 1 workpiece. In this equivalent comparison, using Berlt CBN inserts increased efficiency by 100% and reduced overall tooling costs by 45%.

IV. Why Choose Berlt CBN Inserts

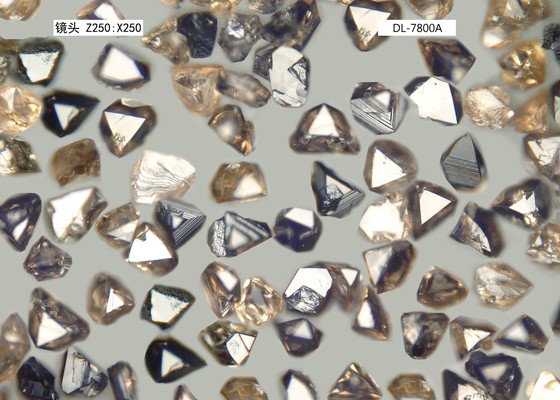

In the field of CBN tools, the source of the material determines the upper limit, manufacturing capability determines stability, and application experience determines the final outcome. Berlt not only produces CBN inserts but also has in-depth mastery of the CBN material itself.

Our core advantages lie in:

Source-Level Material Capability: Independent control from CBN powder to PCBN composite materials ensures consistent quality.

Large-Scale Manufacturing Strength: Large-scale, stable production capacity guarantees batch delivery and long-term supply.

Proven Application Experience for Wind Power Bearings: Mature tool geometries and parameter systems developed for different specifications and operating conditions.

We always believe: A truly valuable tool is not about being cheap to buy, but about being reliable to use.

Choosing Berlt CBN inserts means wind power bearing processing no longer has to be a "tough nut to crack," but can instead easily shift into "high gear." We look forward to becoming your reliable, long-term, and mutually beneficial partner.