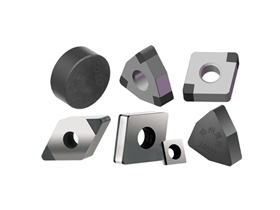

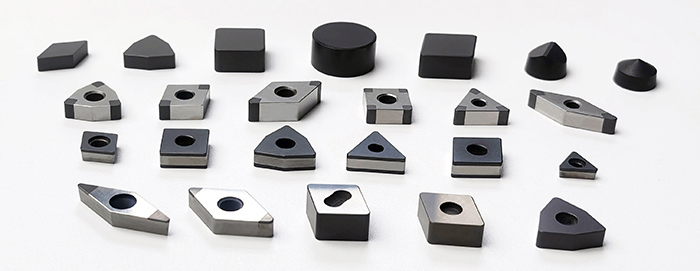

Cubic Boron Nitride (CBN) inserts are one of the preferred tools for machining high-hardness materials (HRC50-65) and difficult-to-machine materials. Compared with traditional carbide tools, CBN has extremely high hardness and thermal stability, enabling high-precision and high-efficiency machining on workpiece materials such as cast iron and hardened steel.

However, the cutting principle of CBN inserts differs from the traditional shearing of soft materials; its core mechanism is plastic extrusion and scraping.

1.Traditional Cutting vs. CBN Hard Turning

Traditional Cutting: For example, in mild steel, when the insert cuts into the material, a shear zone forms ahead of the cutting edge. The material slips along the shear plane to form chips, and the insert mainly withstands shear forces.

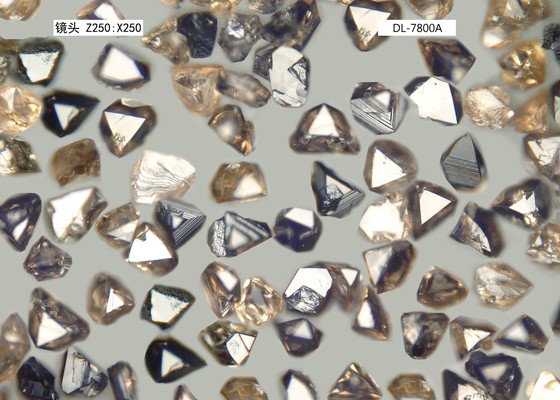

CBN Hard Turning: The workpiece material has high hardness and low plastic deformation capability, making it difficult to form continuous chips through traditional shearing. Due to its ultra-high hardness, the CBN cutting edge hardly deforms. During cutting, the workpiece material undergoes plastic flow along the cutting edge, and the chips are "extruded". The cutting force is mainly in a state of compression + micro-extrusion.

Therefore, from a mechanical perspective, CBN cutting is essentially a combined mechanism of "extrusion-scraping".

2.Characteristics of Cutting Forces

· Main cutting force is relatively high: Because the material is compressed into the extrusion zone in front of the tool.

· Cutting temperature is concentrated in the chip rather than the tool: CBN is resistant to high temperatures, so the tool temperature increases slightly, reducing wear.

· Special chip morphology: Usually appears as thin flakes or intermittent small pieces; chip flow resembles scraping rather than continuous shearing.

3.Why it Can Replace Grinding

· The cutting surface generated by extrusion and scraping is smooth and dimensionally stable.

· CBN inserts are less prone to chipping and can perform high-precision turning on hardened layers.

· Process simplification: Hardened parts may not require grinding or grinding steps can be reduced.

In its development process, Berlt Company continuously develops CBN tool materials matched to the performance of the processed materials. It currently possesses over 80 "fully automatic peripheral grinding machines", key equipment for manufacturing CBN tools, forming the largest domestic production capacity for CBN inserts. Contact us to obtain a machining solution tailored for you.