Against the backdrop of the manufacturing trend towards "harder materials, faster cycle times, and higher efficiency," an increasing number of difficult-to-machine materials (such as hardened steel, cast iron, sintered alloys, etc.) are appearing in production processes. Traditional carbide tools and ceramic tools struggle to meet the demands of high hardness, high wear resistance, and high-temperature machining.

Consequently, cubic boron nitride (CBN) superhard inserts have become a focus of industry attention. With their outstanding performance on high-hardness materials, they have become an important tool for the manufacturing industry in tackling difficult-to-machine materials.

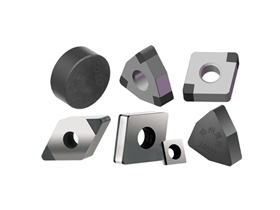

Core Advantages of Cubic Boron Nitride (CBN) Inserts

1、Extremely high hardness and wear resistance. CBN material hardness can reach 3000~5000 HV. When turning difficult-to-machine materials, its wear resistance can be up to 50 times greater than that of carbide tools.

2、Excellent thermal stability and thermal conductivity. CBN inserts can not only withstand high-temperature environments but also possess excellent thermal conductivity, enabling them to rapidly dissipate cutting heat, thus ensuring greater stability during high-speed machining of hard materials.

3、Strong chemical stability and excellent anti-adhesion properties. When machining ferrous metals like high-hardness steel and cast iron, CBN inserts can avoid issues of tool adhesion or chemical corrosion, ensuring more stable tool performance.

4、Wide range of application, specifically designed for difficult-to-machine materials. CBN inserts are suitable for various difficult-to-machine materials, such as hardened steel, gray cast iron, wear-resistant cast iron, ductile cast iron, etc.

How Manufacturing Enterprises Can Implement the Use of CBN Inserts

1、Identify workpiece material and hardness level. Understand whether the part is made of high-hardness, wear-resistant, heat-treated materials and assess if it is suitable for CBN inserts.

2、Select appropriate insert grade and geometry. Choose the suitable CBN insert material, edge preparation, and chip breaker design based on machining conditions (roughing, finishing, continuous cutting, interrupted cutting, grooving).

3、Optimize cutting parameters and machine tool rigidity. As the cutting conditions for CBN inserts when machining hard materials differ from those of traditional tools, it is necessary to redesign parameters such as cutting speed, feed rate, and depth of cut, and ensure good rigidity of the machine tool and fixture.

4、Monitor tool status and machining quality. Record tool life, machining time, surface roughness, dimensional stability, etc., to evaluate overall economic benefits.

5、Progress from small-batch trial production to gradual promotion. It is recommended to first test CBN inserts on representative parts or key components, accumulate data, and then promote their use comprehensively.

In the context of "increasing material hardness, rising machining difficulties, and dual pressures of efficiency and cost" in manufacturing, CBN inserts, with their material advantages, application value, and mature technical solutions, have become an important tool for manufacturing enterprises to break through machining bottlenecks and enhance production efficiency and cost-effectiveness.

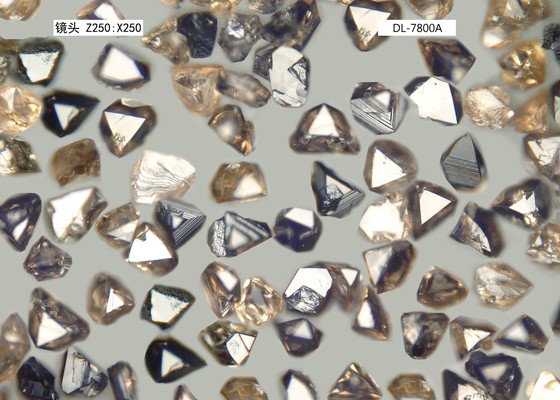

Zhengzhou Berlt, as a pioneer in China's CBN cutting tool industry, owns one of the country's super-large CBN tool production bases. Its products cover over 90% of the domestic market in hard turning and heavy-duty cutting fields. With its self-built CBN (cubic boron nitride) material factory, it guarantees the quality of the insert raw materials from the source. The annual production capacity exceeds 6 million pieces of CBN inserts. Please feel free to contact us for technical support and application solutions regarding CBN inserts.