With the increasing demands for machining accuracy and production stability in components for industries such as bearings, gears, molds, and wind power, hardened steel materials (HRC 58-65) have become common machining targets. Traditional tooling solutions are gradually revealing bottlenecks in terms of stability, efficiency, and cost control, making tool performance a key factor determining machining quality.

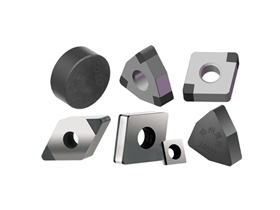

Berlt CBN Hard Turning Inserts are precisely a mature solution developed to address this core need for hard steel machining.

I. Technical Challenges and Industry Consensus in Hard Steel Machining

During the cutting process of hard steel materials, the cutting edge is subjected to continuous high temperature, high pressure, and impact loads. If the tool material lacks stability or the edge grinding is improper, it is highly prone to micro-crack propagation at the cutting edge, ultimately leading to chipping or machining failure.

Therefore, for hard steel machining: tool wear is acceptable, but chipping is not; efficiency can be optimized, but stability must be prioritized.

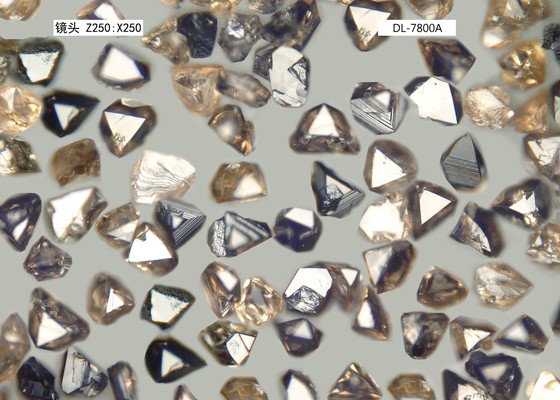

II. CBN Tool Material: Providing Foundational Assurance for Hard Turning

CBN (Cubic Boron Nitride) tool material possesses ultra-high hardness close to that of diamond, while also maintaining good red hardness and chemical stability under high-temperature conditions. When machining ferrous materials like hardened steel and bearing steel, CBN material can effectively suppress diffusion wear and thermal softening phenomena.

Leveraging this material advantage, CBN hard turning inserts can maintain a more stable cutting state during hard steel turning and batch production. This imparts predictable and manageable characteristics to tool life, providing reliable support for large-scale production.

III. Berlt CBN Hard Turning Inserts: Born for Hard Steel Machining

In practical applications, the performance difference of CBN hard turning inserts often lies not in "whether it can cut," but in whether they possess long-term stable edge performance resistant to chipping.

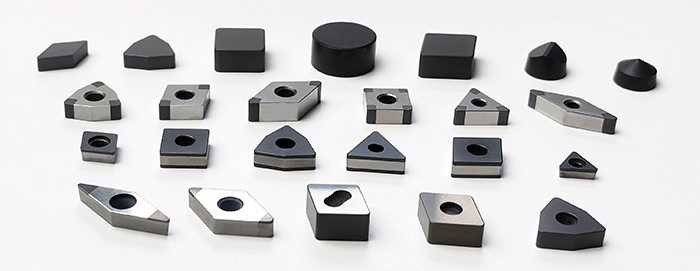

During the R&D and manufacturing of Berlt CBN hard turning inserts, targeted optimizations are applied to the material and cutting edge:

·Control of CBN material crystal structure and density

·Balanced design of tool toughness and wear resistance

·Optimization of micro-edge geometry and grinding quality

Through systematic technical optimization and 100% full inspection of cutting edges, the inserts maintain stable cutting under high-load, high-hardness working conditions, significantly reducing the risk of sudden failure.

In the field of hard steel machining, truly valuable tools are demonstrated not only by single-pass cutting capability but, more importantly, by stable performance in long-term, batch production. What Berlt CBN Hard Turning Inserts offer is a mature machining solution centered on stability and supported by accumulated technical expertise.