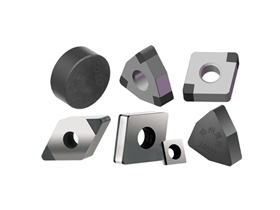

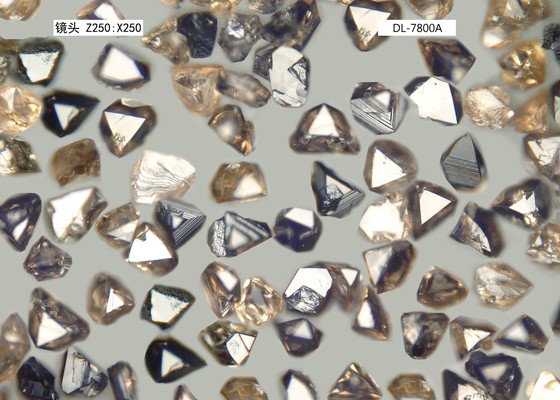

As ultra-hard cutting tools for machining ferrous metals, especially high-hardness and difficult-to-machine materials, CBN inserts are widely used in processing cast iron, hardened steel, and other materials.

However, if CBN inserts are used improperly, a series of problems may occur. Today, Zhengzhou Bote will discuss the common issues, causes, and corresponding solutions when using CBN inserts.

1、Chipping, Fracture, or Premature Breakage

·Issue Phenomenon: Small notches on the cutting edge, large chunks breaking off, or even the entire tool tip fracturing.

·Main Causes: Excessive cutting force (too high feed rate, too deep cutting depth); mechanical impact (hardened layer on the workpiece surface, insufficient machine tool rigidity, or vibration caused by insecure clamping, loose insert installation); incorrect insert grade selection (mismatch between insert material grade and workpiece material grade); insufficient tool tip strength (too small or too large tool nose radius).

·Solutions: Optimize cutting parameters (reduce feed rate, decrease cutting depth); avoid impact (ensure sufficient rigidity of the machine tool and workpiece clamping, ensure inserts and tool holders are securely installed, select the appropriate tool grade); enhance tool tip strength (choose a suitable tool nose radius).

2、Abnormal Wear (Non-Normal Wear)

·Issue Phenomenon: Inserts wear out too quickly, resulting in tool life far below expectations.

·Main Causes: Cutting speed too high (excessive speed causes the tool tip temperature to exceed its stable range); cutting speed too low (low speed places the tool in a state of severe friction, accelerating wear); incorrect insert grade selection (mismatch between workpiece material and CBN grade); workpiece material issues (workpiece material contains elements such as nickel or cobalt that easily react with CBN).

·Solutions: Adjust cutting speed (find the optimal speed range for the current "workpiece material-tool grade" combination); select the correct material (use the appropriate CBN insert material grade).

3、Poor Machined Surface Quality

·Issue Phenomenon: Chatter marks on the workpiece surface, high roughness values, inaccurate dimensions.

·Main Causes: Tool vibration (poor machine tool rigidity, excessively long tool overhang, insecure clamping); worn tool tip (tool nose radius is worn out); improper cutting parameters (feed rate too high or incorrect tool nose radius); low installation accuracy (incorrect tool tip height alignment).

·Solutions: Eliminate vibration (shorten tool overhang, use a more rigid tool holder, check machine tool and clamping conditions); replace with a new insert (timely replacement of worn inserts); adjust parameters (use appropriate cutting parameters); use wiper inserts (if machine tool power and rigidity allow, use CBN inserts with wiper edges).

4、Ineffective Inserts, Unable to Cut Properly

·Issue Phenomenon: Inserts burn out immediately upon use, completely lacking durability.

·Main Causes: Incorrect material usage (CBN inserts cannot be used to machine non-ferrous metals such as aluminum or copper, as CBN will undergo a chemical reaction with these materials); insufficient workpiece hardness (CBN's advantage lies in machining high-hardness materials, while machining soft materials is ineffective).

·Solutions: Material matching (CBN inserts are only suitable for machining high-hardness ferrous metals such as quenched steel, chilled cast iron, gray cast iron, etc.; for soft steel, stainless steel, aluminum alloys, etc., use carbide, ceramic, or diamond inserts instead).