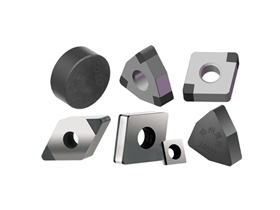

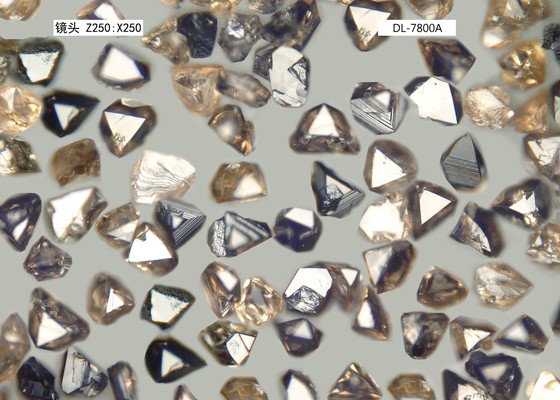

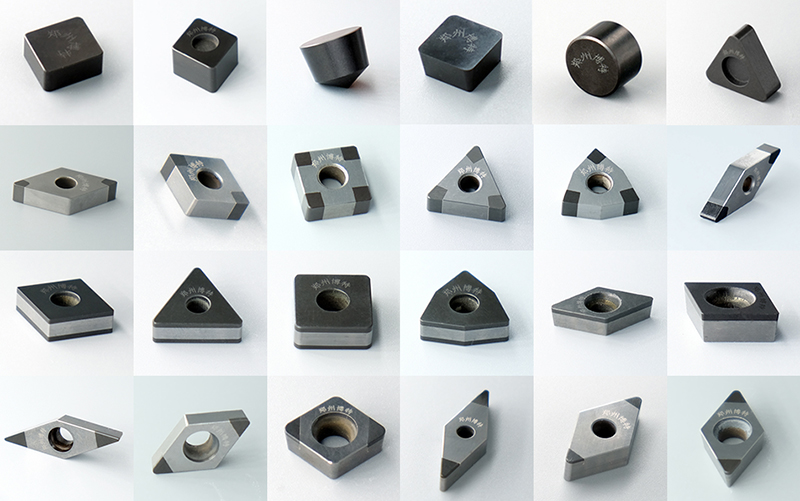

CBN (cubic boron nitride) inserts, due to their extreme hardness (second only to diamond), excellent thermal stability, and chemical inertness, are particularly suitable for machining cast iron and hardened steels with a hardness above HRC 45.

In the practical application of CBN inserts, setting the cutting parameters is more complex and critical than with carbide inserts. The appropriateness of these parameters directly affects machining efficiency, surface quality, tool life, and processing costs.

The main factors influencing CBN insert cutting parameters include:

1、Workpiece Material and Hardness: Materials such as gray cast iron, high-chrome cast iron, hardened steel, and high-speed steel exhibit significant differences in machinability. Therefore, the workpiece material is the first step in determining cutting parameters.

2、Machining Conditions:

Continuous Cutting VS Interrupted Cutting: Turning external diameters typically offers better continuity, allowing slightly higher parameters. Interrupted cutting imposes greater impact on the insert, necessitating a reduction in cutting speed and feed rate, along with selecting a more impact-resistant CBN grade.

Roughing VS Finishing: Roughing prioritizes metal removal rate (MRR), enabling larger depths of cut and feed rates, but cutting speed must consider machine power. Finishing pursues dimensional accuracy and surface finish, requiring reduced feed rates and a moderate increase in cutting speed.

3、Machine Tool Capability and Stability: Factors including machine power, rigidity, spindle accuracy, fixture rigidity, and cooling method all influence the determination of cutting parameters. High-power, rigid machines are the foundation for efficient machining using CBN inserts. Insufficient rigidity leads to tool vibration/chatter, adversely affecting CBN insert performance.

4、CBN Insert Characteristics: The CBN material grade and insert geometry parameters (nose radius, chamfer angle and width, edge preparation, chipbreaker groove, etc.) all have varying impacts on determining suitable cutting parameters.

Determining the optimal cutting parameters for CBN inserts is a dynamic process requiring comprehensive consideration of factors related to the workpiece, tool, machine tool, and machining requirements. Always use the recommended parameters provided by the CBN tool manufacturer (Berlt) as the starting point. Then, based on specific on-site conditions, through careful test cuts, meticulous observation, and systematic adjustments, find the optimal balance point among efficiency, cost, and quality.