In the field of hard steel interrupted cutting, not all CBN inserts can truly solve the problem.

High-hardness materials, high-intensity impact, and high consistency requirements make hard steel interrupted cutting a core scenario that tests the "true capability" of hard turning tools.

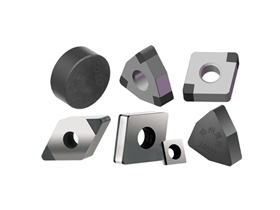

Based on extensive end-user working conditions and internal process validation, Berlt's newly developed CBN hard turning insert grade BTS6000-2 is born precisely for hard steel interrupted cutting characterized by "difficult machining, strong impact, and high stability demands".

I. The Real Challenges of Hard Steel Interrupted Cutting: Beyond Just "Hardness"

In actual production, the hard steel interrupted cutting site commonly faces the following issues:

· High workpiece hardness (HRC55-68), leading to frequent insert chipping and micro-cracks;

· Concentrated cutting heat, rapid thermal decay at the tool tip, resulting in unstable tool life;

· Interrupted cuts/uneven stock, with high-frequency impacts accelerating insert damage;

· High consistency requirements for batch processing, yet often facing frequent tool changes and machine stoppages.

The essence of these problems lies not in "whether it can be machined" but in whether it can be turned stably over a long period.

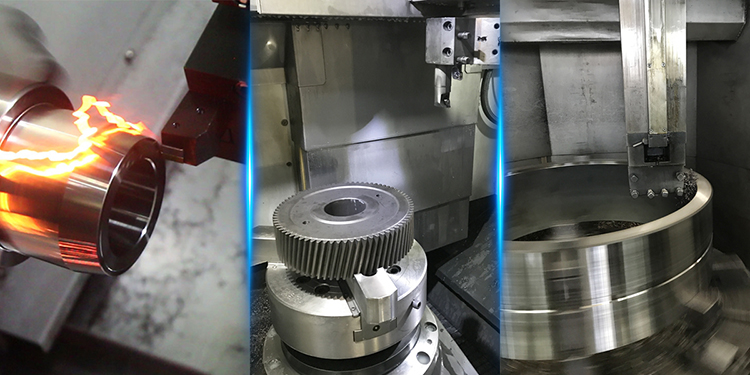

II. Typical Hard Turning Workpiece Categories

The Berlt new BTS6000-2 tool material grade is primarily designed for the following hard turning workpiece types:

· Hardened steel parts (shafts, sleeves, flanges)

· Bearing inner/outer rings, raceway-type parts

· Mold steel, hot-work mold parts

· High-hardness structural parts like gears, splines, transmission components

Grade BTS6000-2 offers a wide applicable hardness range and is especially suitable for interrupted cutting conditions.

III. Berlt BTS6000-2 Grade: The "Stable-Type" CBN Born for Hard Steel Interrupted Cutting

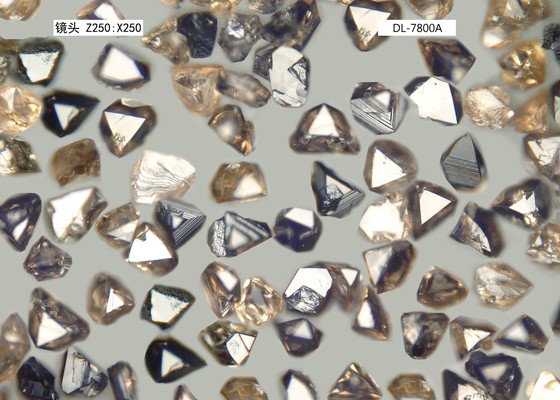

BTS6000-2 is a CBN insert grade independently developed by Berlt specifically for hard steel interrupted cutting, based on its own comprehensive CBN material system and hard turning application data. It employs high-grade CBN powder, adds scientifically proportioned composite binder phase substances, and incorporates toughening nanoparticles, following a material design philosophy that balances wear resistance and impact resistance. It is directionally strengthened for the thermo-mechanical coupled conditions of hard steel interrupted cutting, born specifically for this challenge.

The Berlt BTS6000-2 grade does not pursue "ultimate hardness" but focuses on one core objective: making hard steel interrupted cutting controllable, stable, and replicable.

IV. Core Advantages of Berlt BTS6000-2 Grade in Hard Steel Interrupted Cutting Applications

Stable Resistance to Chipping, Adapts to Severe Interrupted Conditions. The BTS6000-2 grade achieves a balanced optimization in material toughness and structural stability. Under conditions like interrupted cuts, hard spot fluctuations, and uneven stock, it is less prone to sudden chipping, ensuring more secure machining. For example, a customer machining bearing-type parts made of 100CrMo7-3, hardness HRC58–62, found the Berlt BTS6000-2 grade CBN insert achieved comparable tool life to imported coated CBN inserts in actual processing, successfully substituting the imported inserts.

Balanced Wear Resistance, More Predictable Tool Life. The issue with many CBN inserts is not "short life" but unpredictable life: excellent for the first few pieces, then sudden failure. From internal validation and customer testing sites, BTS6000-2 grade inserts show more uniform wear patterns and a gentler life decay curve, making it easier for users to establish tool change schedules.

Strong Thermal Stability, Suitable for Medium-to-High Cutting Speed Hard Turning. In the high-temperature environment of hard turning, the BTS6000-2 grade CBN insert maintains a stable tool tip structure, reducing micro-cracks and early failure caused by heat concentration, making it suitable for batch production machining.

Good Machining Consistency, Reduces Comprehensive Machining Costs. The advantage of the BTS6000-2 grade lies in providing a more stable overall machining rhythm, with more consistent machining dimensions and surface quality. It is more suitable for standardized processes and replicated production, leading to significant reductions in hidden costs for users regarding cost per part, downtime, and manual intervention.

Hard steel interrupted cutting should not rely on luck or repeated trial and error. The Berlt BTS6000-2 grade has completed validation across various hard steel interrupted cutting conditions, demonstrating outstanding stability, consistent tool life, and chipping resistance, designed precisely for batch hard turning.

Leave complex machining challenges to the CBN insert truly born for hard steel interrupted cutting. Please contact Berlt at 400-069-8887 for more trial support and application advice regarding the BTS6000-2 grade CBN hard turning inserts.